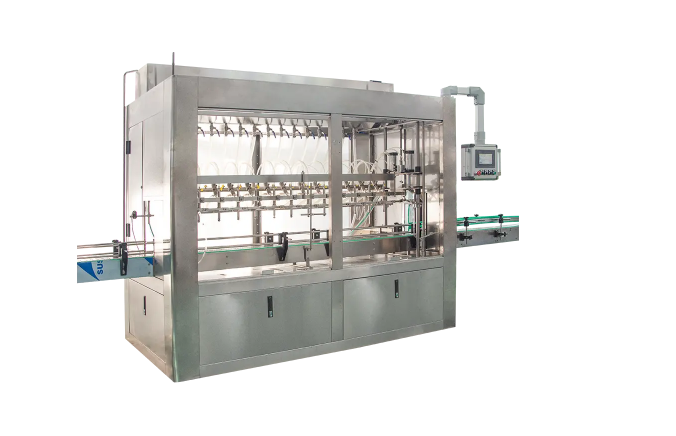

In the competitive personal care field, staying ahead often involves streamlining production. Those companies participate in the shampoo manufacturing industry that uses a shampoo filling machine to automate its filling process enjoy a plethora of compelling benefits that could greatly boost their production both in terms of efficiency and product quality.

Much Faster Production

Shampoo Filling Machine designed and developed to provide speed and efficiency to production lines. This far exceeds [human]filling because these machines can mimic the throughput required from 30 to 120 bottles per minute depending on what the setup is. Faster production speed allows companies to deliver larger orders to customers more quickly, based on market requirement.

Stable precision results, minimized waste of goods.

Product filling requires precision, which is where the shampoo filling machines come in handy. These machines greatly reduce waste by making sure each and every bottle is filled with the precise amount of shampoo per milliliter. By lessening overfill, production expenses are decreased and this accuracy helps abide by industry standards for product volumes.

Flexible Support for Multiple Container Types

State-of-the-art shampoo filling machines are highly versatile and can fill shampoo bottles in various sizes, from small travel-size containers to jumbo economy sizes. This flexibility is especially useful for companies who manufacture both a diverse portfolio of products and a portfolio of packaging options, enabling fast changeovers from one production run to another without protracted downtime for reconfiguration.

Improved Safety and Hygiene

Automating the filling of shampoo helps with safety even more by minimizing how much can you have be manually handled, which lowers dramatically the possibility of an injury happening at work. Machines are operated enclosed which eliminate the risk of contamination and therefore the product goes from the production to the customer pure and uncontaminated.

Cost Savings Over Time

The same can be said about the costs involved and though the investment required in a shampoo filling machine can be high, the ultimate amount you can save makes it a sensible choice. The three basic saving you get is a reduced labor force cost, product waste, and the ability to make large volumes more efficiently reducing overall production cost as escalated as possible. Additionaly, the reliable quality from automated filling can keep your customers happy and coming back for more which will result to more sales.

When you bring a shampoo filling machine into your line, you're not just evolving your operation: you're preparing for the future in an industry with a lot of potential, and a lot of competition. The process is an obvious befit to any shampoo manufacturer hoping to improve its scale economically and responsibly; able producing large quantities of product fast, and with a high degree of precision, while still maintaining product quality